SHUANGQIN MACHINERY

Product Categories

SHUANGQIN MACHINERY

Recommended Products

ABOUT US

Guangdong Shuangqin Machinery Co., Ltd.

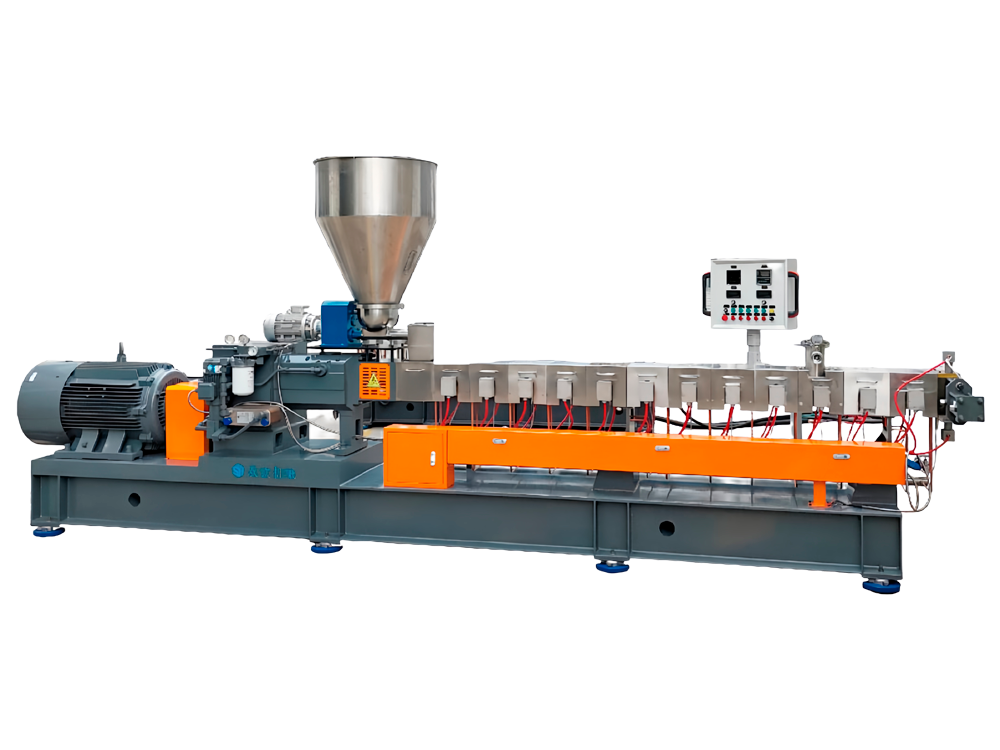

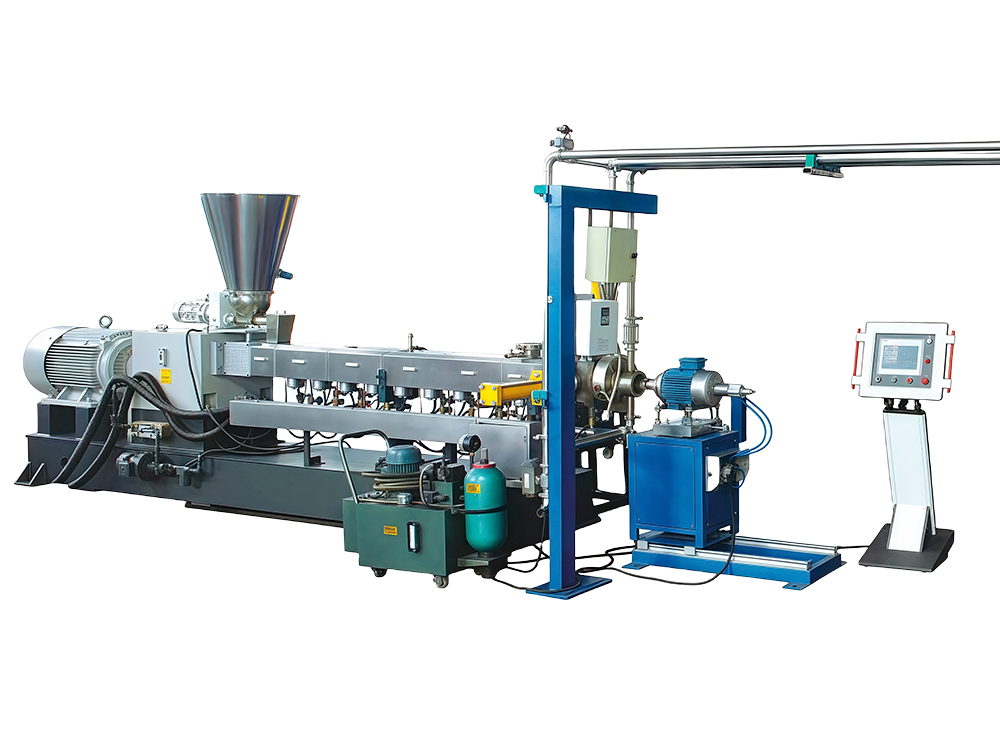

Guangdong Shuangqin Machinery Co., Ltd. is a high-tech enterprise specializing in the research and development, production, processing, technology transfer, and technical services of twin-screw extrusion units and accessories. The company has a group of senior engineering and technical personnel and a professional after-sales service team. We believe that high-quality products and professional services are the future of the company. The company is constantly striving to create "excellent products," incorporating a large amount of customer on-site usage experience into its rational design, making our equipment more practical.

We have rich theoretical and practical experience in the compounding and modification of high polymers and melt extrusion. Products are mainly applicable to PA, PP, PE, PBT, ABS:, PPS, PS, PPO, LCP, TPR, TPE, SEBS, and other plastics for flame retardancy, reinforcement, filling, and co-blending. We have created considerable economic benefits for our customers and are highly praised by our users.

SHUANGQIN MACHINERY

Why Choose Us

High-efficiency three-screw structure combined with high-torque transmission, low-energy consumption mixing, 600r/min high-speed adaptation to high-filling process, 50% increase in production capacity, specializing in modified plastics and cable materials.

Air-cooled/water ring/underwater multi-mode granulation system, SQJ two-stage unit flexible expansion, adaptable to all types of production from color masterbatch to biodegradable materials, meeting complex process requirements.

Pre-sale customization + lifetime after-sales support, 24-hour spare parts response, one-year free three-guarantees, regular optimization of production line efficiency, ensuring zero risk for customer operations.

Empowerment through Mature Applications

Verified by thousands of cases, focusing on engineering plastics modification and high-value-added products (XLPE cable materials, biodegradable masterbatches, etc.), optimizing parameters to ensure 99.9% purity particles, and enhancing market competitiveness.

SHUANGQIN MACHINERY

Industry Applications

SHUANGQIN MACHINERY

Blog & News

2025.05.27

A Strong Alliance: Machinery and Suppliers Join Hands to Secure Parts Supply

2025.05.27

2025.05.27